After 15 years in the CNC machining industry at AIXI HARDWARE, I’ve learned that choosing the right material is often more critical than selecting the perfect cutting tool. Every week, clients ask me the same question: “What material should I use for my project?” The answer isn’t always straightforward, but understanding material properties and machining different materials can save you thousands of dollars and weeks of production time.

Today, I want to share what I’ve learned about CNC machining materials – from the aluminum parts that launched my career to the exotic titanium components we machine for aerospace clients. This isn’t textbook theory; it’s real-world experience from someone who’s made every mistake in the book and learned from each one.

Understanding Material Classifications and Properties

When I started at AIXI HARDWARE, I thought all metals were basically the same – just cut them fast and move on. I was wrong. Each material family has distinct characteristics that directly impact your machining strategy, tool selection, and final part quality.

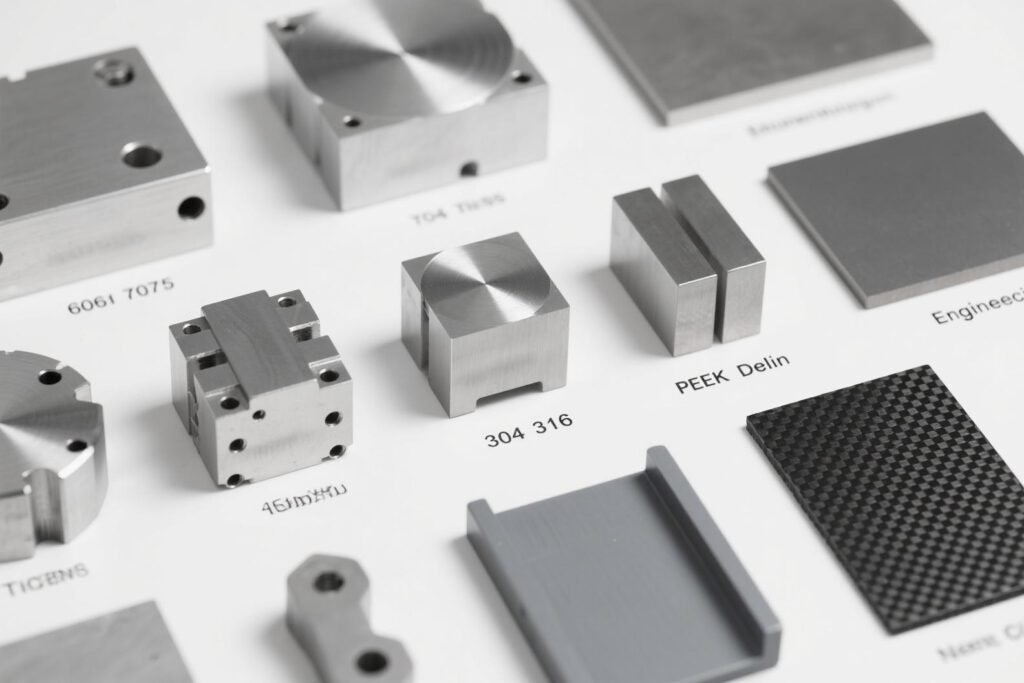

Materials fall into three main categories for CNC work: metals, engineering plastics, and composites. But within each category, the variations are enormous. Take aluminum, for instance. 6061-T6 machines completely differently from 7075-T6, even though they’re both aluminum alloys. The difference in cutting speeds, feed rates, and tool wear can be dramatic.

The key properties that matter most in CNC material selection are machinability rating, thermal conductivity, work hardening tendency, and chip formation characteristics. I’ve seen perfectly planned production runs fail because someone ignored thermal expansion coefficients or didn’t account for residual stress patterns.

Metal Materials Machining Guide

Aluminum Alloy Series

Aluminum remains my favorite material to machine, and for good reason. At AIXI HARDWARE, we process tons of aluminum monthly, from simple brackets to complex aerospace housings. The 6000 series alloys are incredibly forgiving for beginners, while the 7000 series offers strength that rivals some steels.

6061-T6 is the workhorse of our shop. It machines beautifully at high speeds – we typically run 800-1200 SFM with carbide tooling. The chips evacuate cleanly, surface finishes are excellent, and dimensional stability is predictable. I remember my first big 6061 job: 500 complex brackets for a robotics company. We held ±0.005″ tolerances across the entire run without a single reject.

7075-T6 requires more respect. It’s stronger but also more prone to work hardening if you’re not aggressive enough with cutting parameters. We’ve found success running slightly lower speeds (600-900 SFM) but maintaining aggressive feed rates. The key is consistent chip load – hesitate, and you’ll work harden the surface.

2024-T3 aluminum presents unique challenges due to its copper content. Tool wear accelerates, and you need excellent flood coolant to manage heat. We reserve this alloy for aerospace applications where its strength-to-weight ratio justifies the additional machining complexity.

Stainless Steel Grades

Stainless steel taught me patience. Unlike aluminum’s forgiving nature, stainless punishes poor technique immediately. Work hardening happens fast, and once you’ve hardened a surface, recovery is nearly impossible.

304 stainless is relatively manageable. We machine it at 200-300 SFM with positive rake tooling and consistent feed rates. The secret is never letting the tool rub – maintain constant cutting action or face the consequences of work hardening.

316 stainless adds molybdenum, which improves corrosion resistance but complicates machining. Tool life drops compared to 304, and we’ve learned to use more aggressive cutting parameters to stay ahead of work hardening. Sharp tools are absolutely critical – dull tools spell disaster with 316.

17-4 PH stainless in the H900 condition is one of the most challenging materials we regularly machine at AIXI HARDWARE. It’s incredibly strong but also incredibly abrasive. We use ceramic inserts for roughing operations and reserve carbide for finishing. Even then, tool life is measured in minutes, not hours.

Titanium Alloy Applications

Titanium represents the ultimate machining challenge. Ti-6Al-4V is our most common titanium grade, primarily for aerospace and medical applications. After years of trial and error, we’ve developed reliable processes, but it’s never routine.

The key with titanium is managing heat generation. Titanium’s poor thermal conductivity means heat stays at the cutting edge, accelerating tool wear. We machine at relatively low speeds (150-250 SFM) but with high feed rates to keep chips moving and heat controlled. Flood coolant isn’t optional – it’s survival.

Tool selection matters enormously. We use uncoated carbide for most operations, though some newer coated grades show promise. Sharp cutting edges are critical; even slightly worn tools will work harden titanium surfaces rapidly.

Special Alloy Materials

Inconel 718 pushes our capabilities to the limit. This superalloy is used in jet engine components where operating temperatures exceed 1500°F. Machining it requires specialized tooling, aggressive coolant strategies, and patience.

We machine Inconel at very low surface speeds (50-100 SFM) with ceramic or CBN tooling. The material work hardens instantly if cutting parameters drop below critical thresholds. Power requirements are enormous – our heaviest machines struggle with large Inconel components.

Hastelloy C-276 presents similar challenges but with added chemical resistance requirements. We’ve developed specific protocols for handling these exotic alloys, including specialized workholding to manage the extreme cutting forces involved.

Engineering Plastics Processing Points

Plastic machining seems easier than metals, but different challenges emerge. Thermal management becomes critical – plastics have low melting points and poor heat dissipation. Chip evacuation strategies change completely, and surface finish requirements often exceed what’s possible with metals.

PEEK (Polyetheretherketone) is our most commonly machined engineering plastic at AIXI HARDWARE. It’s expensive but offers exceptional chemical resistance and temperature stability. We machine PEEK with sharp, polished tooling at moderate speeds (300-500 SFM) with minimal or no coolant – excess coolant can cause dimensional issues as parts cool.

PTFE (Teflon) machines unlike anything else. It’s soft, sticky, and chips poorly. We use extremely sharp tools with large rake angles and very light cuts. Workholding is challenging because clamping forces can deform parts easily.

Delrin (POM) machines beautifully when parameters are correct. It produces excellent surface finishes and holds tight tolerances. However, it’s sensitive to heat – too much generates formaldehyde gas and causes dimensional instability.

Nylon varieties each have unique characteristics. Glass-filled nylons are abrasive and accelerate tool wear, while standard nylons can be gummy and difficult to achieve good surface finishes. We’ve found that climb milling with very sharp tooling produces the best results.

Composite Materials Handling Technology

Carbon fiber composites represent our newest expertise area at AIXI HARDWARE. These materials combine incredible strength with light weight, but machining them requires completely different approaches from traditional materials.

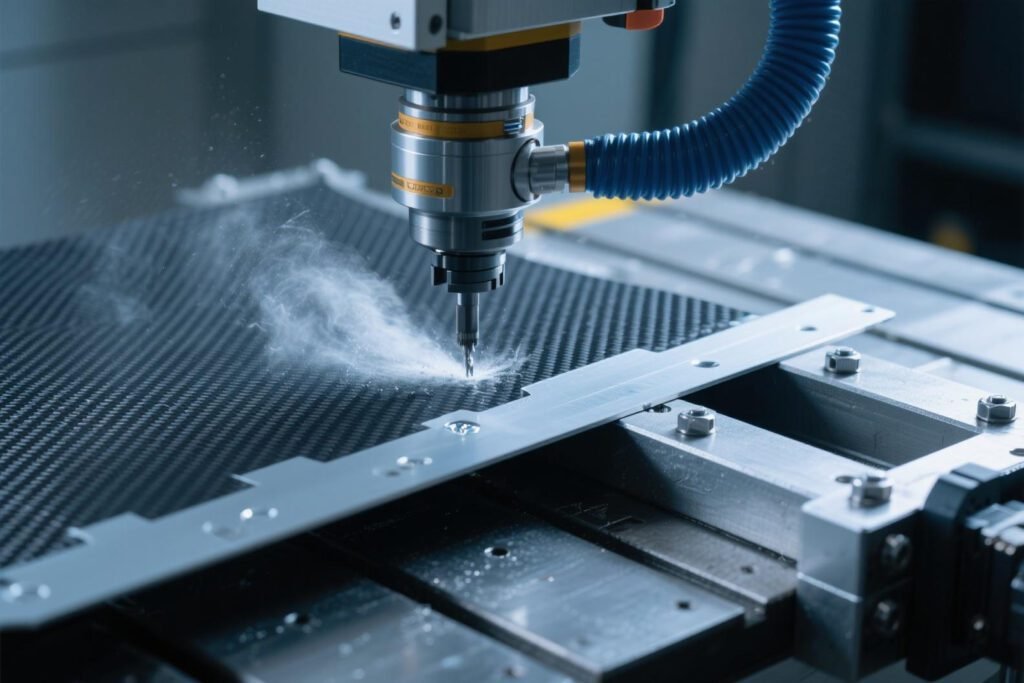

Carbon fiber reinforced plastics (CFRP) are extremely abrasive. Diamond-coated tooling is often necessary for production quantities. Dust collection becomes critical – carbon fiber dust is hazardous and conductive, creating potential equipment damage beyond health concerns.

We machine CFRP with very high speeds (1000+ SFM) and relatively low feed rates. Sharp tools are essential – dull tools don’t cut fibers cleanly, leading to delamination and poor surface finish. Backing plates are often necessary to prevent exit-side damage.

Fiberglass composites are less abrasive than carbon fiber but still challenging. The glass fibers dull cutting edges rapidly, and the resin matrix can cause chip evacuation problems. We use compressed air rather than coolant to avoid delamination issues.

Material Selection Decision Framework

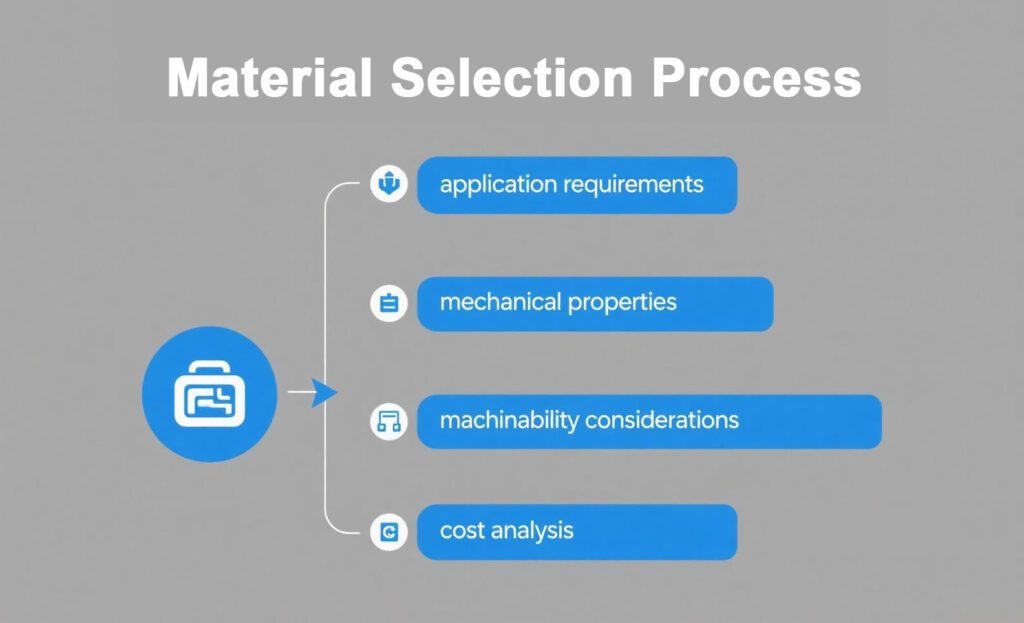

Choosing the right material involves balancing multiple factors: mechanical properties, machinability, cost, and application requirements. At AIXI HARDWARE, we’ve developed a systematic approach to CNC material selection that considers all these variables.

Start with application requirements: What loads will the part see? What’s the operating environment? Are there specific certifications required? These questions narrow your material options significantly.

Next, consider manufacturing constraints: What tolerances are required? What surface finishes are needed? How many parts are you making? High-volume production might justify difficult-to-machine materials if the performance benefits are significant.

Cost analysis comes last, not first. I’ve seen too many projects fail because material costs were optimized without considering machining costs. A cheaper material that requires twice the machining time often costs more overall.

We maintain a material selection matrix that scores materials across key criteria: machinability (1-10 scale), strength-to-weight ratio, corrosion resistance, cost index, and availability. This systematic approach prevents emotional decision-making and ensures consistent results.

Machining Parameters Optimization

td {white-space:nowrap;border:0.5pt solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

MaterialSurface Speed (SFM)Feed Rate (IPM)Depth of CutTool MaterialCoolant Strategy

| 6061-T6 Aluminum | 800-1200 | 20-50 | 0.200″ | Carbide | Flood or Mist |

| 7075-T6 Aluminum | 600-900 | 15-40 | 0.150″ | Carbide | Flood |

| 304 Stainless | 200-300 | 8-20 | 0.100″ | Carbide | Flood |

| Ti-6Al-4V | 150-250 | 5-15 | 0.050″ | Uncoated Carbide | Flood |

| Inconel 718 | 50-100 | 3-8 | 0.030″ | Ceramic/CBN | High-Pressure |

| PEEK | 300-500 | 10-25 | 0.100″ | HSS/Carbide | Minimal/None |

| Carbon Fiber | 1000+ | 5-15 | 0.020″ | Diamond Coated | Air Blast |

These parameters represent starting points based on our experience at AIXI HARDWARE. Actual optimization requires testing with your specific setup, tooling, and part geometry.

Cost Comparison Analysis

Material costs are just the tip of the iceberg. Total part cost includes material, machining time, tooling consumption, setup costs, and quality control requirements. Here’s what we’ve learned about true costs:

Aluminum offers the best overall value for most applications. Material costs are reasonable, machining is efficient, and surface treatments are readily available. Tooling life is excellent, and setup times are minimal.

Stainless steel costs 2-3x more than aluminum in material, but machining time often doubles due to lower cutting speeds. Tool consumption increases significantly. However, the corrosion resistance often justifies the added expense.

Titanium represents premium pricing at every level. Material costs are 10-20x aluminum prices, machining time triples, and tooling costs are enormous. We only recommend titanium when its unique properties are absolutely necessary.

Engineering plastics vary widely in cost. PEEK approaches titanium pricing, while Delrin costs less than aluminum. Machining time is typically shorter than metals, but tooling requirements can be specialized and expensive.

Composites have high material costs and require specialized tooling and handling procedures. However, the weight savings and performance characteristics often justify the expense in aerospace and automotive applications.

Conclusion

Understanding CNC machining materials transforms you from someone who makes parts to someone who engineers solutions. Every material choice impacts part performance, manufacturing cost, and delivery schedule. At AIXI HARDWARE, we’ve learned that investing time in proper CNC material selection saves multiples of that time during production.

The key is building experience systematically. Start with forgiving materials like 6061 aluminum, master the fundamentals, then gradually expand into more challenging materials. Document everything – cutting parameters, tool life data, surface finish results. This database becomes invaluable for future projects.

Remember that material selection isn’t just about the part – it’s about the entire manufacturing system. Consider your equipment capabilities, operator skill levels, and quality requirements. The “best” material on paper might not be the best choice for your specific situation.

Whether you’re machining your first aluminum prototype or tackling exotic superalloys, the principles remain consistent: understand your material, respect its characteristics, and optimize your process accordingly. The investment in learning proper techniques pays dividends throughout your career.