When I first started working with oil and gas clients fifteen years ago, I quickly learned that this industry doesn’t forgive shortcuts. A single component failure on an offshore rig can cost millions, not to mention the safety risks. At AIXI HARDWARE, we’ve built our reputation by understanding these stakes and delivering CNC oil gas machining solutions that perform when it matters most.

Understanding the Unique Demands of Oil & Gas

The petroleum industry operates in some of the world’s harshest environments. I remember visiting a client’s facility in the North Sea – the combination of saltwater spray, extreme temperatures, and constant vibration from drilling operations creates conditions that would destroy ordinary components within months.

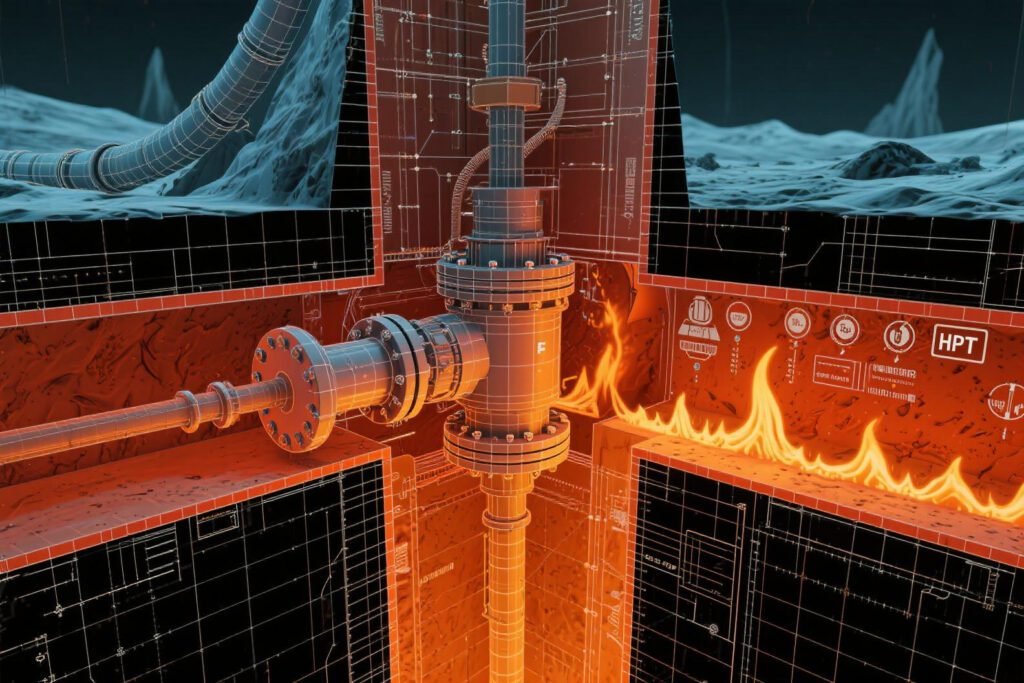

Petroleum equipment parts must withstand pressures exceeding 15,000 PSI, temperatures ranging from -40°F to 400°F, and corrosive environments that would eat through standard materials. This isn’t just about making parts that work – it’s about engineering components that maintain their integrity when human lives depend on them.

The regulatory landscape adds another layer of complexity. Every component must meet strict API (American Petroleum Institute) standards, and in many cases, additional certifications like NACE (National Association of Corrosion Engineers) are mandatory. These aren’t suggestions – they’re non-negotiable requirements that shape every aspect of our machining process.

Material Selection: The Foundation of Reliability

Choosing the right material is where experience really shows. Over the years, I’ve seen too many projects fail because someone tried to save costs on materials. In offshore machining applications, this approach always backfires.

For most oil and gas applications, we start with duplex stainless steels like 2205 or super duplex grades like 2507. These materials offer excellent strength-to-weight ratios and superior corrosion resistance. I particularly favor 2507 for subsea applications – it’s more expensive upfront, but the long-term reliability is worth every penny.

Inconel alloys are our go-to choice for high-temperature applications. Inconel 625 and 718 have saved more than one project where extreme heat would have caused standard materials to fail. I once worked on a downhole tool project where the operating temperature reached 350°F continuously. Only Inconel could handle those conditions while maintaining the precise tolerances required.

For rotating equipment and valve components, we often specify 17-4 PH stainless steel. Its combination of strength, corrosion resistance, and machinability makes it ideal for critical applications. The material can be heat-treated after machining to achieve specific hardness requirements – typically HRC 28-32 for most petroleum applications.

Conquering High-Pressure, High-Temperature Challenges

Working with HPHT (High Pressure, High Temperature) components requires a completely different mindset. Traditional machining approaches simply don’t work. The thermal expansion alone can throw tolerances off by thousandths of an inch if you’re not careful.

We’ve developed specialized fixturing systems that account for thermal growth during machining. For a recent blowout preventer project, we had to maintain tolerances of ±0.0005″ on components that would experience temperature swings of 200°F during operation. Our solution involved temperature-controlled machining environments and fixtures designed to compensate for material expansion.

Stress relief becomes critical in these applications. We typically perform intermediate stress relief cycles during machining, especially for thick-walled components. This prevents distortion and ensures dimensional stability throughout the part’s service life. I learned this lesson the hard way early in my career when a $50,000 wellhead component warped after final machining because we skipped the stress relief step.

Critical Components That Keep Operations Running

Every piece of equipment in the oil and gas industry serves a critical function, but some components are truly make-or-break. Valve bodies and trim components top this list. A failed valve in a high-pressure system can cause catastrophic failures. We machine these components to API 6A standards, with particular attention to sealing surfaces and pressure ratings.

Wellhead equipment presents unique challenges. These components must seal against extreme pressures while allowing for thermal expansion and operational stresses. We use specialized boring techniques to achieve the surface finishes required – typically 32 RMS or better on sealing surfaces.

Blowout preventer (BOP) components are perhaps the most critical safety items we manufacture. These devices must operate flawlessly when called upon, often after sitting idle for months in harsh environments. Every surface finish, every tolerance, every material property must be perfect. There’s no room for “good enough” when lives are at stake.

For rotating equipment like compressor components and pump parts, dynamic balancing becomes crucial. We’ve invested in high-precision balancing equipment that can achieve G2.5 balance grades or better. This level of precision prevents premature bearing failures and reduces maintenance requirements.

Navigating Safety Certifications and Standards

The certification process in oil and gas is complex but absolutely essential. API certifications form the foundation, but depending on the application and location, additional standards may apply. NACE MR0175/ISO 15156 compliance is mandatory for sour service applications, where hydrogen sulfide creates extreme corrosion conditions.

We maintain API Q1 certification at AIXI HARDWARE, which demonstrates our commitment to quality management systems specific to the petroleum industry. This certification requires regular audits and continuous improvement processes that have made us better manufacturers overall.

ATEX certification is required for equipment used in explosive atmospheres – common in oil and gas facilities. This affects not just the final product but also our manufacturing processes and documentation requirements. Every step must be traceable and verifiable.

Quality Standards That Actually Matter

In this industry, quality isn’t just about meeting specifications – it’s about exceeding them consistently. We perform 100% dimensional inspection on critical components, using coordinate measuring machines (CMMs) with accuracies of ±0.0001″. But beyond dimensions, material properties are equally important.

Positive Material Identification (PMI) testing is performed on every heat of material we receive. We’ve caught material mix-ups that could have led to catastrophic failures in the field. Non-destructive testing (NDT) is routine – liquid penetrant testing, magnetic particle inspection, and ultrasonic testing are all part of our standard quality procedures.

Pressure testing is required for many components. We have pressure test capabilities up to 20,000 PSI in our facility, allowing us to verify performance before shipment. I’ve seen too many projects delayed because components failed pressure testing after installation – it’s much better to catch issues early.

Building Reliable Supply Chains

Supply chain reliability in oil and gas machining is about more than just on-time delivery – it’s about ensuring continuity of operations in remote locations where downtime costs can exceed $100,000 per day.

We maintain strategic inventory of common materials and standard components. For critical applications, we often recommend clients maintain spare parts inventory based on failure analysis and maintenance schedules. Our inventory management system tracks material certifications, heat numbers, and traceability information required for oil and gas applications.

Supplier qualification is rigorous. Every supplier in our network undergoes regular audits to ensure they meet our quality standards. We’ve developed long-term relationships with material suppliers who understand the critical nature of our applications and maintain appropriate quality systems.

Middle East Market: Unique Opportunities and Challenges

The Middle East represents one of the world’s largest markets for petroleum equipment parts, but success here requires understanding local requirements and business practices. We’ve been supplying this region for over eight years, and the experience has taught us the importance of cultural sensitivity and relationship building.

Local content requirements are becoming increasingly important. Many Middle Eastern countries now require certain percentages of local manufacturing or assembly. We’ve developed partnerships with local facilities to meet these requirements while maintaining our quality standards.

Desert environment considerations add another layer of complexity. Sand infiltration, extreme temperature variations, and UV exposure all affect component design and material selection. We’ve developed specialized coatings and treatments specifically for desert applications.

Project Management: Lessons from the Field

Managing oil and gas machining projects requires a different approach than typical manufacturing projects. Lead times are often critical – production delays can cost millions. We’ve learned to build realistic schedules that account for material procurement, certification requirements, and potential quality issues.

Documentation requirements are extensive. Every component must have complete material traceability, dimensional reports, test certificates, and manufacturing records. We use digital documentation systems that provide real-time access to project status and quality data.

Risk management is built into every project plan. We identify potential failure points early and develop mitigation strategies. This might involve qualifying backup suppliers, maintaining safety stock, or developing alternative manufacturing approaches.

Looking Forward: Innovation in Harsh Environment Solutions

The oil and gas industry continues to push boundaries, moving into deeper waters and more challenging environments. Offshore machining requirements are becoming increasingly sophisticated, demanding new materials and manufacturing techniques.

We’re investing in advanced manufacturing technologies like additive manufacturing for complex geometries and specialized tooling. However, the fundamentals remain unchanged – understanding the application, selecting appropriate materials, and maintaining rigorous quality standards.

At AIXI HARDWARE, we’ve built our reputation by delivering solutions that work in the real world. Whether it’s a subsea valve body that must operate flawlessly at 10,000 feet below sea level or a wellhead component that must seal against 15,000 PSI for years without maintenance, we understand what it takes to succeed in this demanding industry.

The oil and gas sector will always present unique challenges, but with the right combination of experience, technology, and commitment to quality, these challenges become opportunities to demonstrate what precision manufacturing can achieve. After fifteen years in this industry, I’m still learning, still improving, and still excited about the next challenging project that comes through our doors.