As a veteran who has worked in the CNC machine industry for 15 years and the Engineering Manager at AIXI HARDWARE, I have witnessed Chinese CNC manufacturers grow from “followers” to “runners-up,” and now they are starting to “lead” in some specialized areas. Today, I want to share this topic with you because many friends have been asking me: “How far have Chinese CNC machines developed? Which brands are worth paying attention to?”

The “Triple Jump” of China’s CNC Machine Industry

I still remember when I started in 2008. When we talked about China CNC machine brands, many European customers would smile politely, then turn around to visit German or Japanese booths. Back then, we really lacked confidence – core technology was controlled by others, high-end CNC systems were all imported, and five-axis machines were something we didn’t even dare to dream about.

But the changes over these 15 years can only be described as “earth-shaking.” Especially since the Made in China 2025 strategy was launched, the policy support and technical research efforts from the government level have been unprecedented. I remember at the EMO exhibition in 2019, a German colleague said with emotion: “You Chinese are too crazy. In just a few years, you’ve caught up with our decades of accumulation.”

What’s the situation now? Simply put: we have completely occupied the low-end market, we are rapidly eating into Europe’s share in the mid-end market, and we are starting to make breakthroughs in the high-end market.

2024 China’s Top 10 CNC Manufacturers Latest Ranking

Based on the latest market data and industry reports, let me give you a detailed analysis of the current situation:

-

Haitian Precision – The “New King” of Five-Axis Machines

Haitian Precision is now the undisputed domestic leader. Their market share in five-axis machines has exceeded 5%, which was unimaginable before. I visited their production line last year and saw five-axis machines produced for Boeing suppliers, with precision controlled within 0.003mm, completely reaching aerospace-grade levels.

What impressed me most is that their overseas revenue now accounts for 35%, and they have set up factories in Vietnam and Mexico. This kind of global layout shows they are no longer satisfied with being “China’s Haitian,” but want to become “World’s Haitian.”

-

Pinnacle – The “Tech Fanatic” of High-Speed Spindles

Pinnacle has made remarkable breakthroughs in high-speed spindle technology in recent years. From 12,000 rpm to 15,000 rpm, and positioning accuracy of 0.005mm, every number behind represents countless days and nights of technical research.

There’s a rumor that they have already got orders from Tesla. You know how demanding Tesla is with suppliers. Being able to enter their supply chain shows that Chinese machining centers quality has been recognized by top international manufacturers.

-

Topstar CNC – The “Specialist” in Aerospace

Topstar CNC is preparing to list on the Hong Kong Stock Exchange recently, which has attracted much attention from the entire industry. They rank first in China’s aerospace five-axis CNC machine market with a market share of 11.6%.

I have a friend working at COMAC. He told me that with C919 aircraft mass production now, the demand for the entire aerospace supply chain has exploded. Topstar CNC, as a leader in this field, has orders scheduled until the second half of next year.

-

Kede CNC – The “Benchmark” of Independent Control

What I admire most about Kede CNC is their persistence. When everyone was buying imported CNC systems, they insisted on self-research. Now their domestic production rate has reached 95%.

I heard recently that they have entered the semiconductor equipment manufacturing field and have cooperation with SMIC. This cross-border move from aerospace to semiconductors shows the technical strength and market sensitivity of Chinese CNC companies.

-

Beijing Jingren – The “Veteran Strong Player” in Precision Machining

Beijing Jingren has always been the big brother in the high-precision engraving machine field, with a market share of 16.3% as stable as a rock. Their equipment is now exported to Europe, and you know Europe is famous for its strict precision requirements.

-

Neway CNC – The “Dark Horse” in Export Markets

Neway CNC has performed quite well in overseas markets in recent years, with exports accounting for more than 30% of revenue. Especially in the Russian market, due to geopolitical factors, their demand for heavy machine tools has exploded, and Neway CNC seized this opportunity.

-

Qinchuan Machine – The “Expert” in Gear Processing

Qinchuan Machine is the absolute leader in gear processing equipment, with a market share of over 30% in new energy vehicle gear equipment. With the explosive growth of the new energy vehicle industry, their prospects are very promising.

-

Zhejiang Heidenhain – The “Rising Star” of Internationalization

Zhejiang Heidenhain saw overseas revenue grow 508% year-on-year last year. This number is simply amazing. They set up factories in Southeast Asia, doubled their turning center exports, and are typical “quietly making big money” type companies.

-

Anchor Danly – The “Professional” in Special Processing

Anchor Danly has unique advantages in special material processing and recently got big orders from Saudi infrastructure projects. The Middle East market has high recognition for them, opening new channels for their internationalization.

-

Jinshangjichuang – The “Joint Venture Model” in Precision Lathes

Jinshangjichuang obtained advanced technology through foreign cooperation and has good cost-performance advantages in precision lathes. However, facing fierce competition from domestic brands, their market share has declined somewhat.

Technical Level: From “Following” to “Running Together”

To be honest, in core technology, we still have gaps with top German and Japanese companies, but this gap is rapidly shrinking.

In CNC systems, companies like Huazhong CNC and Guangzhou CNC can already provide complete solutions from low-end to mid-high-end. Although we still need to work hard on high-end five-axis linkage control, we can completely replace imported products in general three-axis and four-axis applications.

In precision control, our leading companies can already achieve micron-level precision, and even nanometer-level in some specialized fields. This was simply impossible 10 years ago.

Reliability is still our weak point. German machines can work continuously for 8760 hours (one year), while our equipment usually needs more frequent maintenance. But the good news is that the gap is shrinking, and we have obvious advantages in quickly responding to customer needs.

Cost Advantage: Not Just “Cheap”

When many people mention Chinese CNC manufacturers, their first reaction is “cheap.” This stereotype is long outdated.

Our cost advantages now mainly show in:

Complete supply chain: From raw materials to core components, domestic suppliers can basically solve everything, greatly reducing procurement costs and supply risks.

Manufacturing efficiency: Automation levels keep improving, plus engineer dividends, manufacturing efficiency is 30-40% higher than European companies.

Customization ability: When customers have special needs, we can respond and customize quickly, while European companies often need several months of evaluation.

Service response: 24-hour response, 48-hour on-site service – this service speed is incomparable to European companies.

Quality Certification: Aligning with International Standards

Now major domestic CNC manufacturers have basically passed ISO 9001 quality management system certification, and many have also obtained CE certification, US UL certification and other international authoritative certifications.

Leading companies like Haitian Precision and Pinnacle have reached international advanced levels in product quality and are widely recognized in high-end applications like automotive and aerospace.

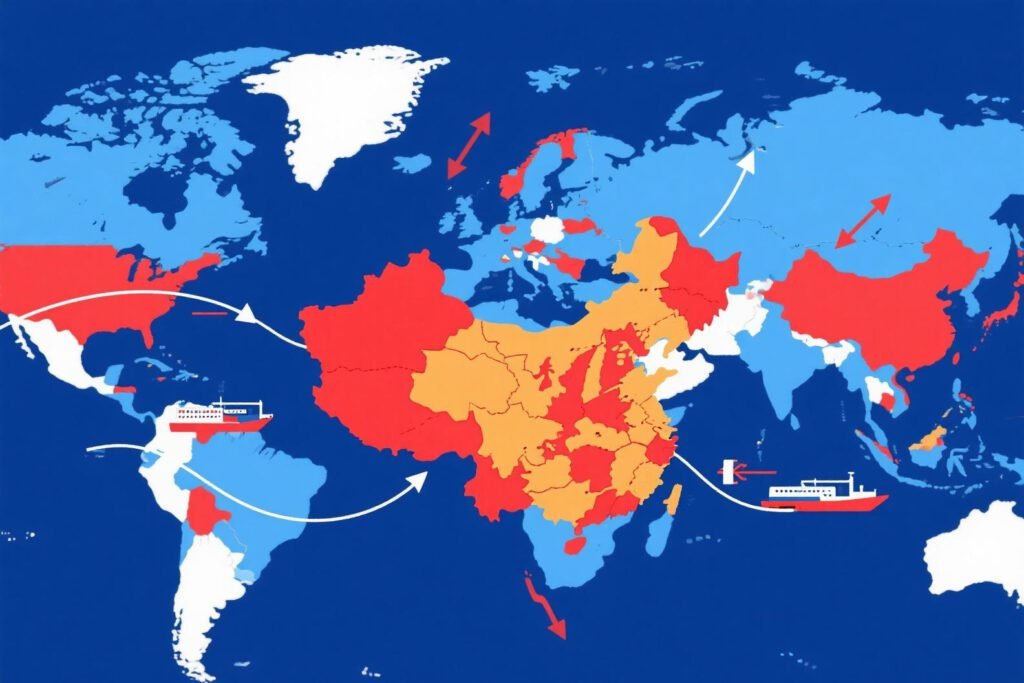

International Markets: From “Going Out” to “Going In”

The performance of China CNC machine brands in international markets in recent years has been impressive:

European market: Although facing technical barriers and trade protection, our advantages in cost-performance and service are winning over more and more European customers. Especially small and medium enterprises, their need for cost control makes them seriously consider Chinese brands.

Middle East market: Infrastructure investment is huge, with strong demand for heavy machine tools. Companies like Neway CNC and Anchor Danly perform excellently in this market.

Southeast Asian market: With manufacturing industry transfer, this market’s demand for Chinese machining centers is growing rapidly. Companies like Zhejiang Heidenhain have already set up factories locally, achieving localized production.

“Belt and Road” markets: Policy support plus product advantages, our market share in these markets keeps expanding.

Investment Value: Long-term Optimistic, Short-term Cautious

From an investment perspective, Chinese CNC manufacturers have obvious long-term investment value:

Policy support: Manufacturing power strategy, specialized and innovative policies all provide strong support for industry development.

Market demand: Manufacturing upgrades, new energy vehicles, aerospace and other emerging industries provide huge market space for CNC equipment.

Technical progress: Driven by new technologies like AI and IoT, smart manufacturing will bring new growth points.

Domestic substitution: In the complex international environment, the demand for localization of key equipment will continue to strengthen.

But in the short term, we need to pay attention to some risk factors: industry cyclical fluctuations, rising raw material prices, international trade frictions, etc.

Final Thoughts

As a veteran in this industry and part of the AIXI HARDWARE team, I am full of confidence in the future of Chinese CNC manufacturers. Although we started relatively late, we have a huge market, complete industrial chain, hardworking engineering teams, and strong government policy support.

A German expert once said: “Chinese people used 30 years to complete our 100-year journey.” This statement is somewhat exaggerated, but it also reflects our development speed from the side.

The question now is not whether Chinese CNC machines work or not, but how to maintain leading advantages in fierce competition, and how to find the balance between technological innovation and market expansion.

I believe that looking back 10 years from now, today might be the key turning point for China CNC machine brands to transform from a “manufacturing giant” to a “manufacturing power.” As industry practitioners, we are fortunate to witness and participate in this great historical process.